The ECS Ball Bearing Drive Conversion

The ECS diesel drive was conceived because all original and aftermarket drive systems that have been and are presently on the market failed to impress the founder and owner of ECS Fabrication Inc., who is an avid "O" scale collector. Other drive systems lack the smoothness and quietness desired and use too much of the motors' energy fighting friction produced between the motor and the locomotives' wheels. Many such units have intermittent binding that cause the locomotive to pulse forward instead of steadily rolling forward, or torque side to side when the motor loads and unloads as its drive train rotates through the "sticky spot". These locomotives have difficulty pulling long, prototypical trains as well. Prototypical speeds and low speed operation ("crawling") are not possible because of these reasons. Some standard and some aftermarket drive systems have visible rotating parts between the fuel tank and the trucks that are not found on prototype locomotives. These systems, known commonly as "tank drives", are undesirable by most because it takes away from the realism of the model. It was at this point, it seemed an old saying said it best, "If you want something done right, do it yourself".

Our drive system was carefully designed on AutoCAD for precision and accuracy. Many things were kept in mind during the design period. Three different prototypes were built before finding perfection. One can not appreciate the silent and smooth operation of our system until seeing one of them operate in person, as many who have witnessed them operate at the "O" Scale Shows since 2004 will attest. We operated our drive system and compared that to how other systems operated at the show with a voltmeter and an ammeter connected to the rails. Our system would smoothly and silently roll back and forth at a setting of just .6 to .7 of a volt. Other systems would take 3.5 to 5.0 volts just to get them to start to move - and not necessarily smoothly or quietly. We were aiming to have the best "O" scale drive on the market and we believe we have done just that. To witness this drive system operate for yourself, ECS Fabrication will be attending the "O" Scale Meet in Chicago in March, 2011. The system will be fully demonstrated right at our exhibit tables throughout the show.

Why do we feel our drive system is the best?

YOU BE THE JUDGE!!!!!

Click on pictures below to enlarge

(Please be advised that pictures are high resolution for detail purposes and may take several seconds to download)

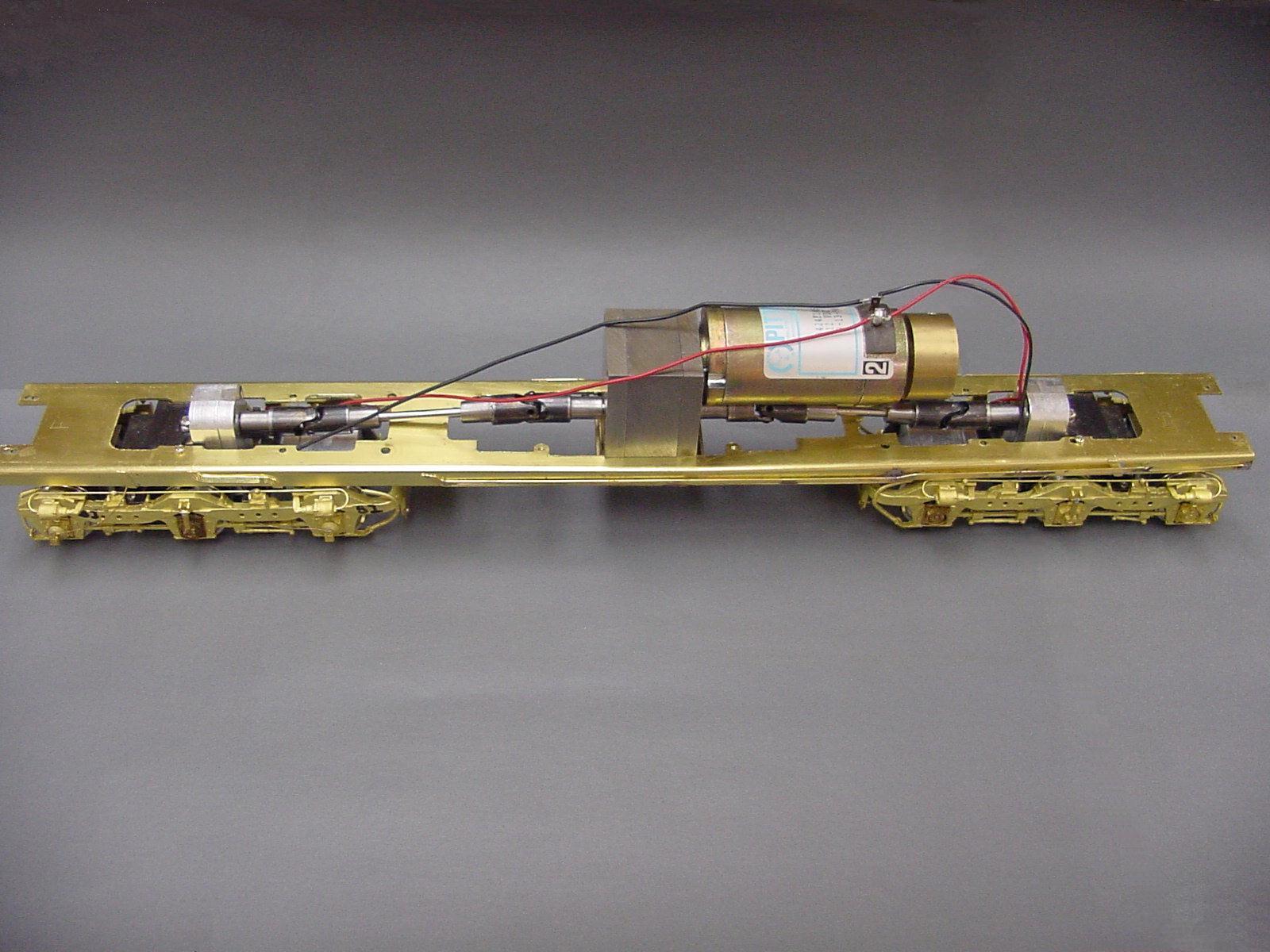

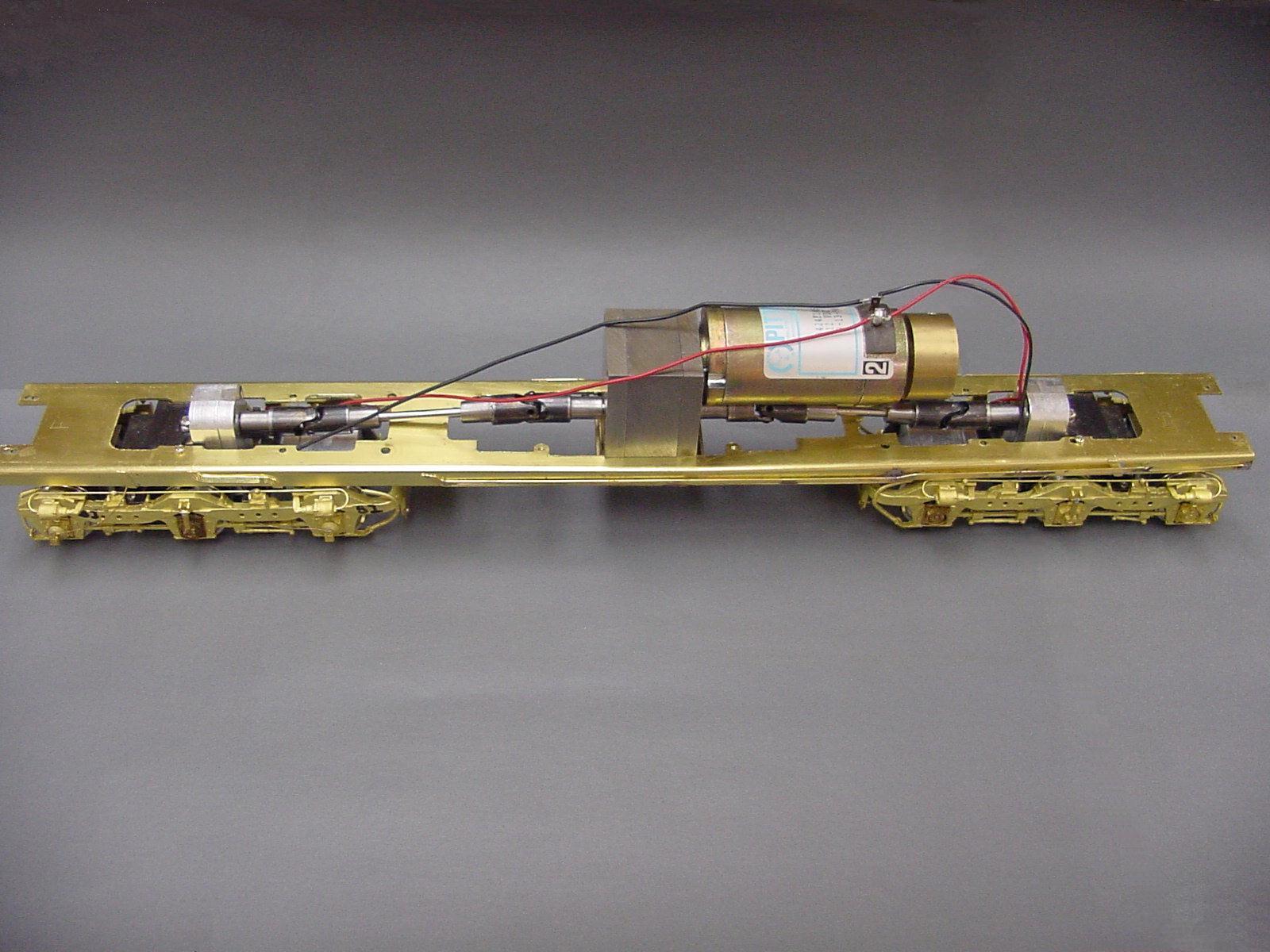

1 - The ECS drive system is constructed with all metal parts and is solid throughout. There are no locations where slippage can occur between the motor and the locomotives' wheels. If the motor is turning - so are the wheels. Some competitors' flywheels make a few or even several revolutions before the locomotive begins to move. This would indicate there is some "slop" in the system somewhere. Plastic belts can stretch and slip on pulleys when under load. Our drive and reduction is all done through gearing with a 15:1 ratio.

2 - The ECS drive system is completely concealed. The motor, reduction box, drive shafts, universal joints and tower heads are all concealed inside the hood. When the model rolls by, its' drive components are not visible as they are on a "tank drive".

3 - The ECS drive system is completely manufactured at our facility. We buy raw stock for reduction boxes, transaxle boxes, universal joints, shafts and gears. We machine all of our own parts. We are not buying parts that someone else makes or stocks from overseas, marking them up and selling them to our customers. We are not buying or using motors with ready made reduction gearing. By manufacturing ALL of our own parts, and YES, hobbing our own gears, we can maintain a level of quality that our competitors just can not match. We can honestly and proudly say that our drive system is MADE IN THE UNITED STATES OF AMERICA!!!!!

4 - The ECS drive system is assembled with ball bearings on each end of every shaft. There are no bushings. Our reduction transmission is also assembled with ball bearings, eliminating any bushings from it as well. Other manufacturers claim to use ball bearings in their drives, but ask them if they have ball bearings in their reduction boxes. By using these bearings, our system produces the least amount of friction possible. Less friction means less strain on the motor and increased efficiency, which results in smoother operation at lower voltages and amperage. With more of the motors' power going to the wheels, longer trains can be pulled - and they can be pulled on the "crawl".

5 - The ECS drive system is quiet as well as smooth. There are 4 reasons for the quiet operation. Firstly, universal joints can make noises when spinning rapidly. Our universals are located AFTER the reduction gearing so that they turn only as fast as the final drive ratio. Secondly, gears can make whisping or whining sounds. If they are not machined to the correct "pitch diameter" or the machine is not set properly to leave a good quality finish at the pressure points on the teeth, noise will be produced when the gears mesh. At ECS, when we turn and part off our gear blanks, we hold the tolerances to +/- .0002 of an inch so our gears do not have "slop" when meshing. We use quality hobs and cutting oils to give the teeth on our gears a top notch finish. Thirdly, reduction gearsets can produce some noise due to the different sizes of the gears and the way their teeth mesh. Our reduction box is made from cast iron which is an excellent sound absorber and deadener. Lastly, our reduction boxes and transaxle boxes are fully lubricated. The lubricant helps stop sound from being made by way of reducing sound producing friction as well as acting as a sound deadener.

6 - The ECS drive system has sealed reduction and transaxle boxes and contain lubricant. All input and output shafts have "O" ring seals.

7 - The ECS drive system is designed to be used in almost any model. Models will require slight modification to the chassis to accept this drive system. Certain models will require the fabrication of a more rigid formed channel chassis which would be quoted before any work would be done. To ensure the best performance and prevent warranty issues, all models to receive this conversion would need to be shipped to our facility for modification and then returned after installation. WE DO NOT PROVIDE COMPONENTS FOR INDIVIDUALS TO INSTALL THEMSELVES. Turn around times would be contingent upon workload at time of order, but should be in the range of twelve to sixteen weeks.

8 - The ECS drive system was designed to be as low profile as possible over the trucks so that it will not easily be seen through radiator screens or interfere with cab floors.

9 - The ECS drive system has a limited lifetime warranty for as long as the purchaser owns the model. Warranty does not cover wheels or motor. Any disassembly of drive components or attempts to modify components will void warranty. Any impact the model may incur that will cause the model to sustain moderate to major damage may result in complete or partial nullification of warranty. Any service work done to the model, should the need ever arise, must be done by ECS Fabrication Inc. or a certified ECS dealer.

10 - WE GUARANTEE THAT OUR DRIVE SYSTEM WILL NOT BE OUT- PERFORMED, OUT-PULLED OR OUT-LASTED BY ANY PRODUCTION OR AFTERMARKET "O" SCALE DRIVE SYSTEM ON THE MARKET.

STANDARD DRIVE INCLUDES:

Installation of complete drive train conversion as shown at top of page. Spur gears are made of brass and the original bushings are used in the truck journal boxes.

Does not include motor or wheels. The motor on the model will be reused as well as the wheels unless specified by customer. If a special motor or certain wheels are desired, the customer will need to either supply them or we can issue a quote for supplying them. Some models may require more extensive modification. For example, our drive requires that the chassis be rigid, some models have a plastic chassis, or flat sheet brass that is not rigid. If a formed brass channel would need to be fabricated, or new bolsters machined, it would be at an additional cost. No extra modifications will be made until approved by model owner.

Standard Drive Pricing:

4 axle - E-mail for pricing

6 axle - E-mail for pricing

8 axle (D-D) - E-mail for pricing

8 axle (B-B-B-B) - E-mail for pricing

OPTIONS:

For those who really want friction free operation, we can press ball bearings into the journal boxes so the axles turn more freely.

For added wear resistance, the brass spur gears can be replaced with steel spur gears. Please be aware that steel spur gears will be slightly noisier than the brass. This option is aimed more toward museum pieces which will see unlimited operation.

For added silence, use phenolic spur gears instead of brass or steel.

For any additional custom work, such as dual motors, modifying "hi-rail" models with scale wheels and lowering to scale height (see customer pictures and comments) please ask for a quote.

Options Pricing (add to standard price above):

Bearings in Journal Boxes -- E-mail for pricing

Steel Spurs in place of Brass - E-mail for pricing

Phenolic Spurs in place of Brass - E-mail for pricing

8400 Series Ball Bearing Pittman Motor - E-mail for pricing

Wiper pickups (necessary if not OEM) - E-mail for pricing

It may be true that our drive system is one of the more expensive drives on the market, but to quote another old saying, "You get what you pay for".

email us at Info@ecsfabrication.com

please type "diesel drive" in the subject box of your message

ace="Trebuchet MS, Arial, Helvetica">